Mass Monitoring in details.

Designed to give you a piece of mind

Optimized surveillance, but how?

Mass Monitoring uses various types of strain gauge. This technology can measure the strain (the stress / the load) in the metal and thereby provide a measurement of the weight inside the silo on the basis of the load on the metal.

The signal from the strain gauge is being transmitted to an amplifier, that turns it into a digital value. The amplifier is hereafter linked to a GSM-module that sends the data to a Mass Monitoring database.

The GSM-module makes use of a SIM card to be independent of the client’s network and hereby increase security. Should you wish to make use of already existing networks, this can be arranged. All measuring tools will be updated from a secure FTP-server, which is owned by Mass Monitoring to secure a safe and reliable solution.

With the HJT Mass Monitoring you get many unique advantages.

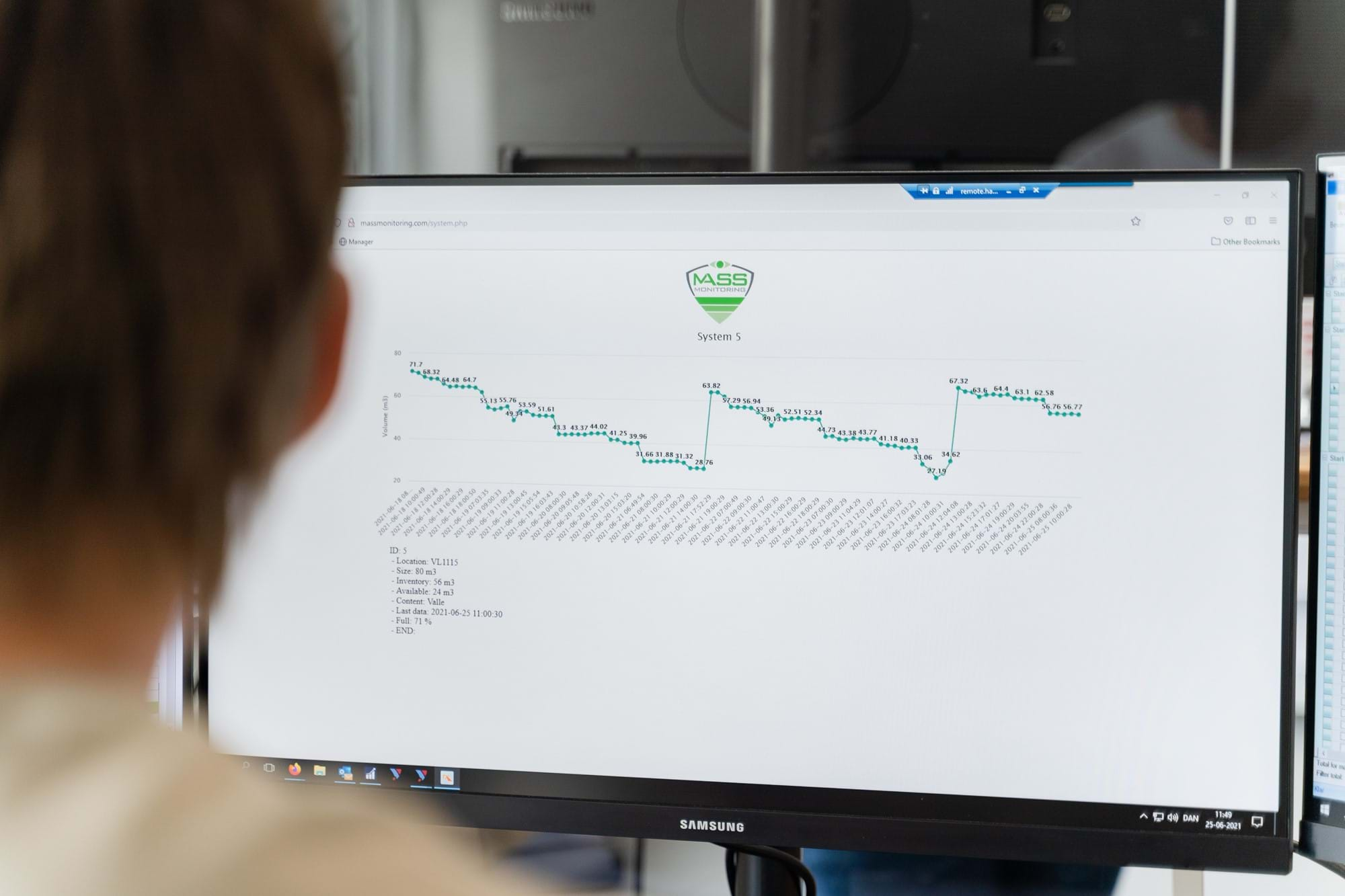

A quick and clear overview of all your silo and tank contents.

Valid data for an optimized planning of storage and purchase.

No waisted driving. With valid data the intervals and the amount of the transportations are based on real data.

Mass Monitoring releases resources for your core activities.

The user interface is easy to access with your user login and gives an intuitive and user-friendly overview.

With Mass Monitoring you get access to your data 24/7.

Let go of the insecurity

Optimized surveillance = reduced costs

With Mass Monitoring, we revolutionize the way me manage your tank storage. The technology is designed with you and for you to make your workday more comfortable.

More advantages:

- Avoid production shutdowns due to an empty tank

- No urgent loads due to lack of storage

- Optimization of bookings, loading sizes, and cargo

- Green approach to carrier optimization

- Storage reduction and reduced inventory levels

- Automatic storage booking

- Increased security regarding supplies

- More persons who watch the storage